Free OKR Templates

Download templatesA non-profit organization is a group focused on addressing a social, cultural, or environmental need rather than generating profit for private owners. These organizations typically work on causes such as education, healthcare, poverty alleviation, environmental conservation, and community development, aiming to create positive change and improve lives.

Non-profits fund their initiatives through donations, grants, and volunteer support. They often collaborate with other organizations, governments, and stakeholders to maximize their impact. The funds are used exclusively to advance their mission through services, research, or advocacy.

Driven by a belief in social good, non-profits prioritize making a meaningful difference rather than financial gain. They engage with communities and corporations to foster a culture of generosity and ensure resources reach those in need.

15 OKR Templates for Non-Profit Organizations

1. Challenge: Lack of Awareness About the Organization’s Mission

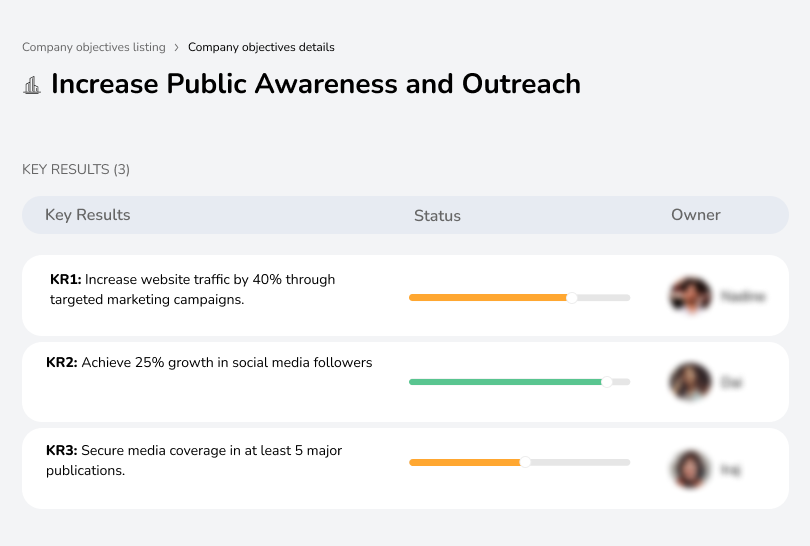

Objective: Increase Public Awareness and Outreach

Owned by: Non-Profit Organization

Due date: 12 months

- KR1: Increase website traffic by 40% through targeted marketing campaigns.

- KR2: Achieve 25% growth in social media followers.

- KR3: Secure media coverage in at least 5 major publications.

2. Challenge: Low Donor Retention Rate

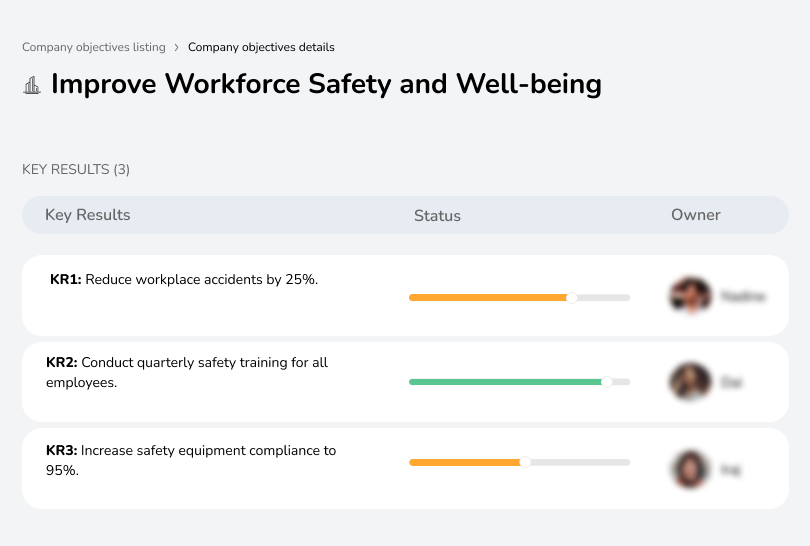

Objective: Improve Workforce Safety and Well-being

Owned by: Non-Profit Organization

Due date: 12 months

- KR1: Increase donor retention rate by 30%.

- KR2: Launch a monthly donor appreciation program.

- KR3: Achieve a 20% increase in repeat donations.

3. Challenge: Limited Fundraising Success

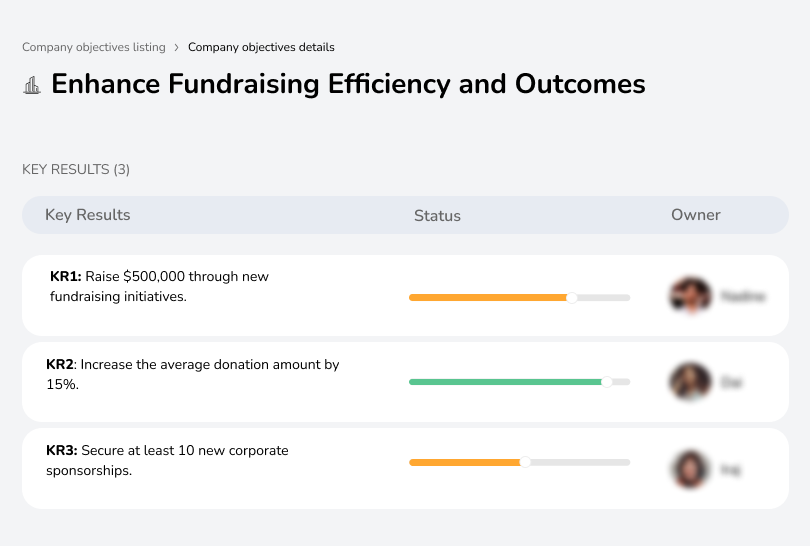

Objective: Enhance Fundraising Efficiency and Outcomes

Owned by: Non-Profit Organization

Due date: 12 months

- KR1: Raise $500,000 through new fundraising initiatives.

- KR2: Increase the average donation amount by 15%.

- KR3: Secure at least 10 new corporate sponsorships.

4. Challenge: Ineffective Volunteer Management

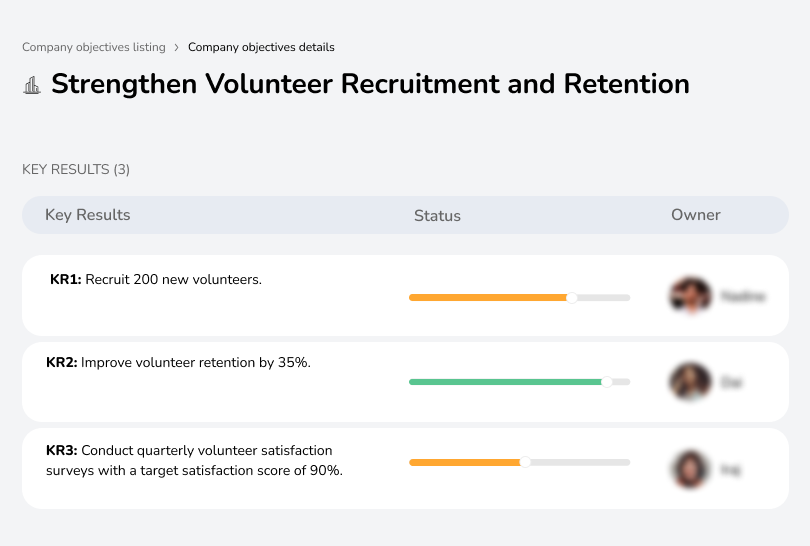

Objective: Strengthen Volunteer Recruitment and Retention

Owned by: Non-Profit Organization

Due date: 12 months

- KR1: Recruit 200 new volunteers.

- KR2: Improve volunteer retention by 35%.

- KR3: Conduct quarterly volunteer satisfaction surveys with a target satisfaction score of 90%.

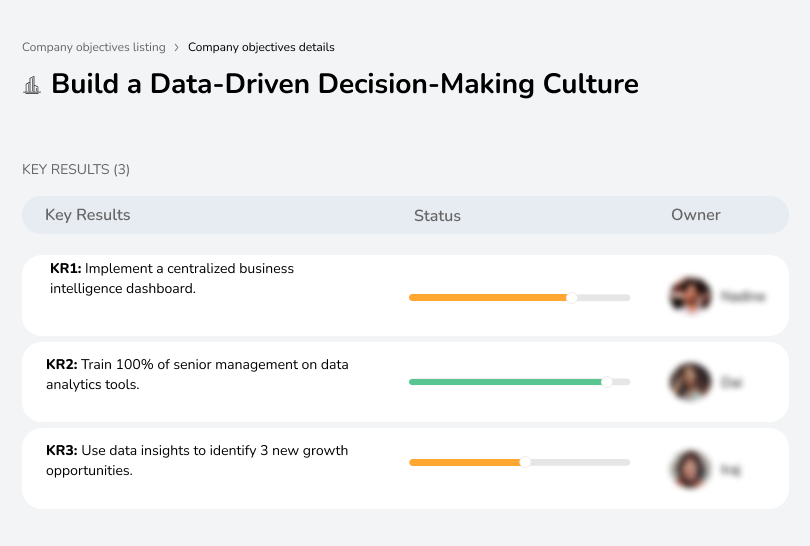

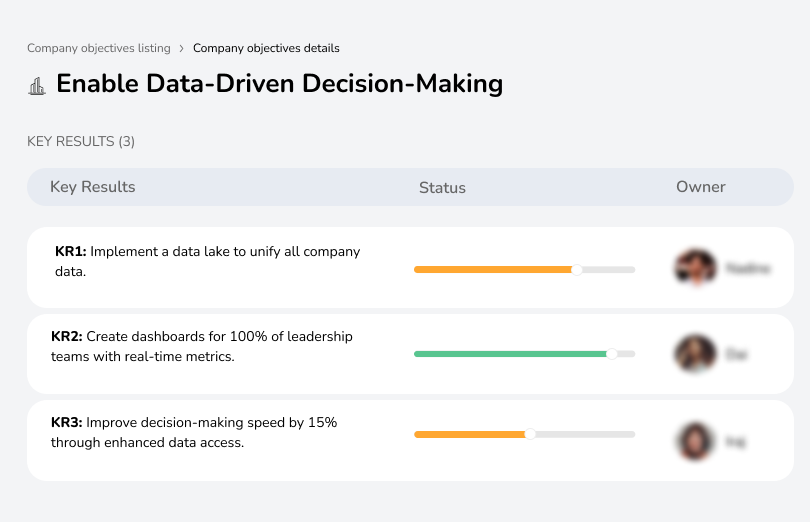

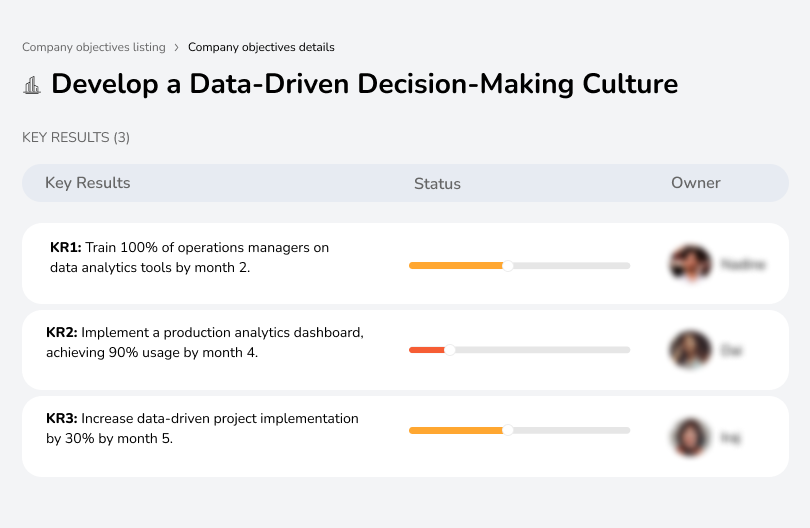

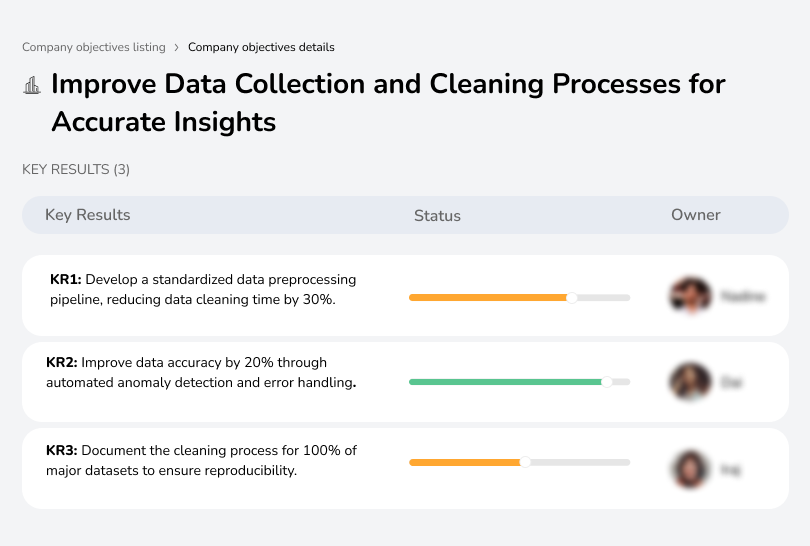

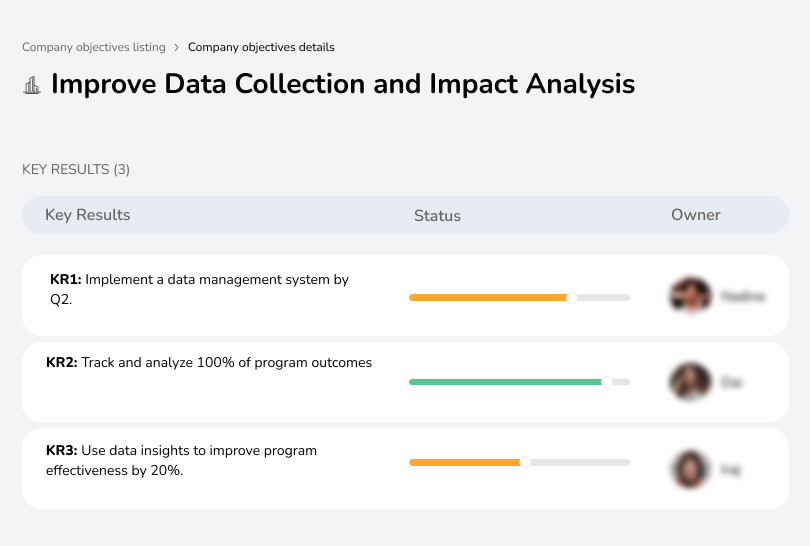

5. Challenge: Lack of Data-Driven Decision-Making

Objective: Improve Data Collection and Impact Analysis

Owned by: Non-Profit Organization

Due date: 12 months

- KR1: Implement a data management system by Q2.

- KR2: Track and analyze 100% of program outcomes.

- KR3: Use data insights to improve program effectiveness by 20%.

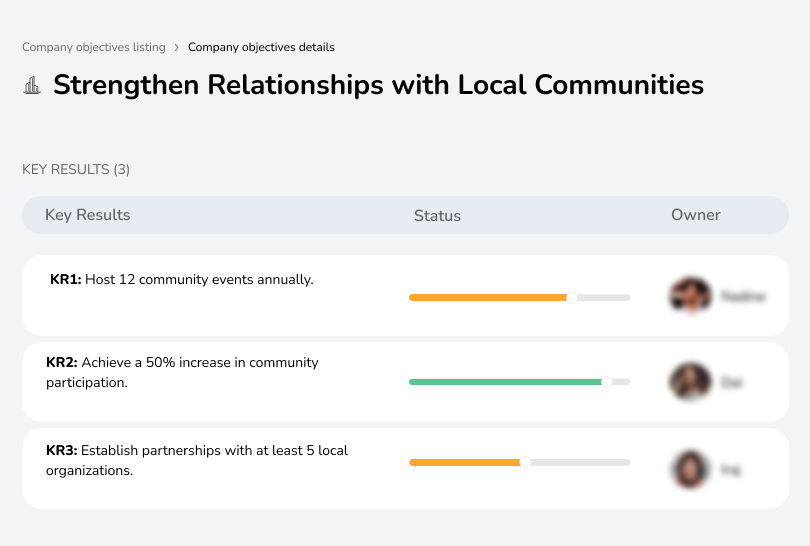

6. Challenge: Inconsistent Community Engagement

Objective: Strengthen Relationships with Local Communities

Owned by: Non-Profit Organization

Due date: 12 months

- KR1: Host 12 community events annually.

- KR2: Achieve a 50% increase in community participation.

- KR3: Establish partnerships with at least 5 local organizations.

Plant Manager (Manufacturing) Templates: Click here

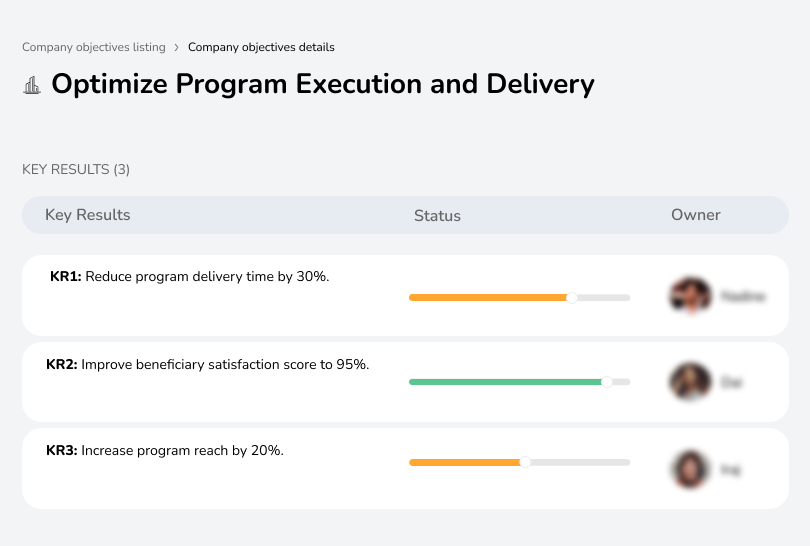

7. Challenge: Inefficient Program Delivery

Objective: Optimize Program Execution and Delivery

Owned by: Non-Profit Organization

Due date: 12 months

- KR1: Reduce program delivery time by 30%.

- KR2: Improve beneficiary satisfaction score to 95%.

- KR3: Increase program reach by 20%.

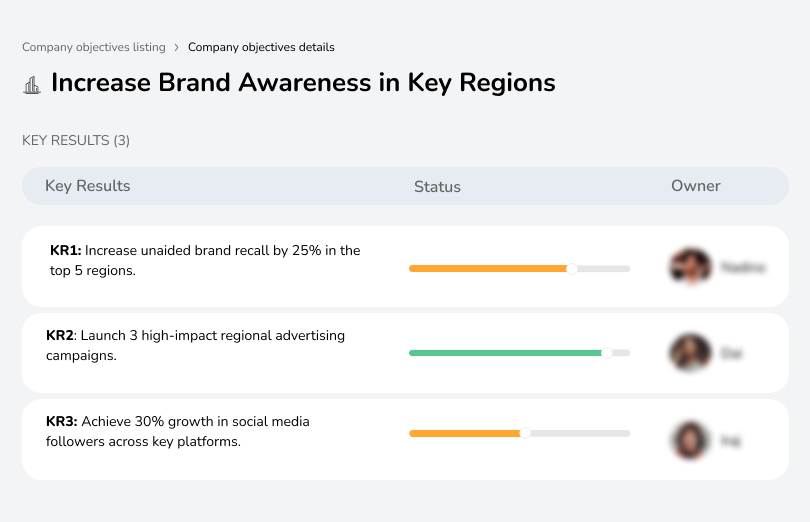

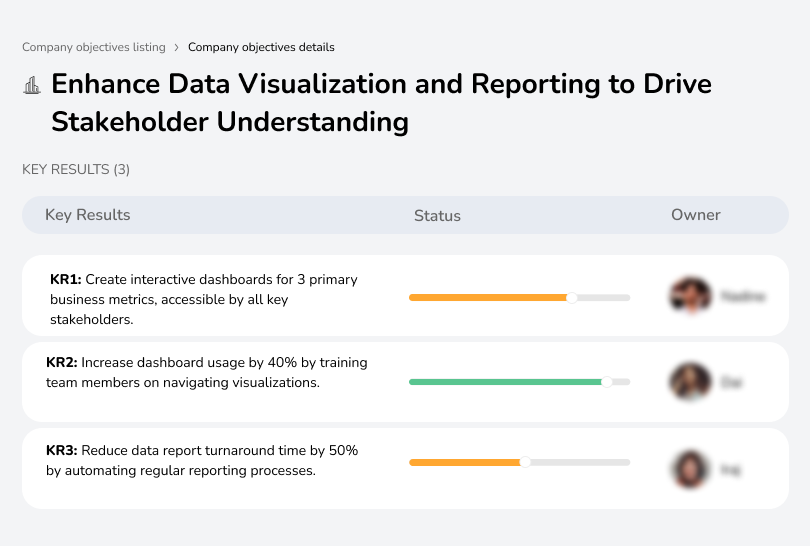

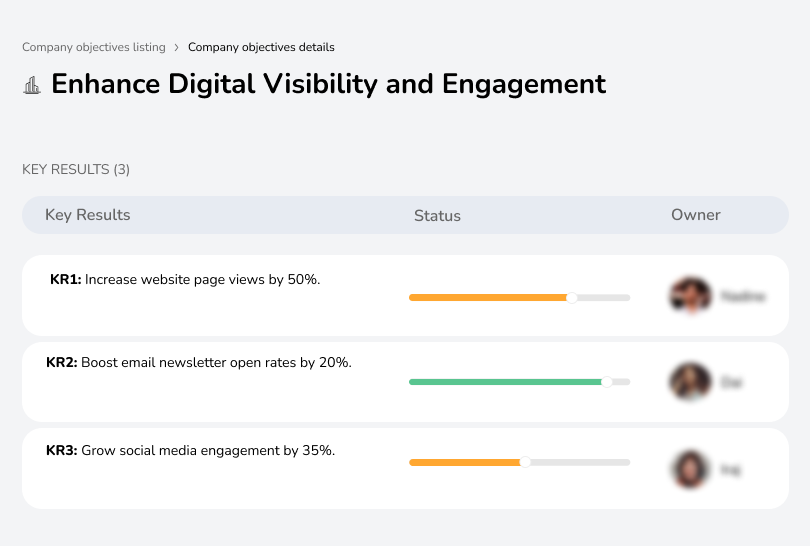

8. Challenge: Insufficient Online Presence

Objective: Enhance Digital Visibility and Engagement

Owned by: Non-Profit Organization

Due date: 12 months

- KR1: Increase website page views by 50%.

- KR2: Boost email newsletter open rates by 20%.

- KR3: Grow social media engagement by 35%.

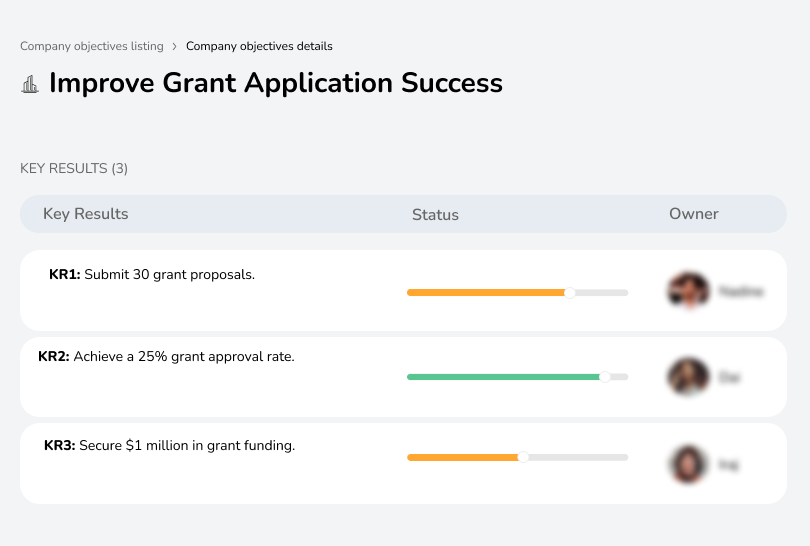

9. Challenge: Low Grant Approval Rate

Objective: Improve Grant Application Success

Owned by: Non-Profit Organization

Due date: 12 months

- KR1: Submit 30 grant proposals.

- KR2: Achieve a 25% grant approval rate.

- KR3: Secure $1 million in grant funding.

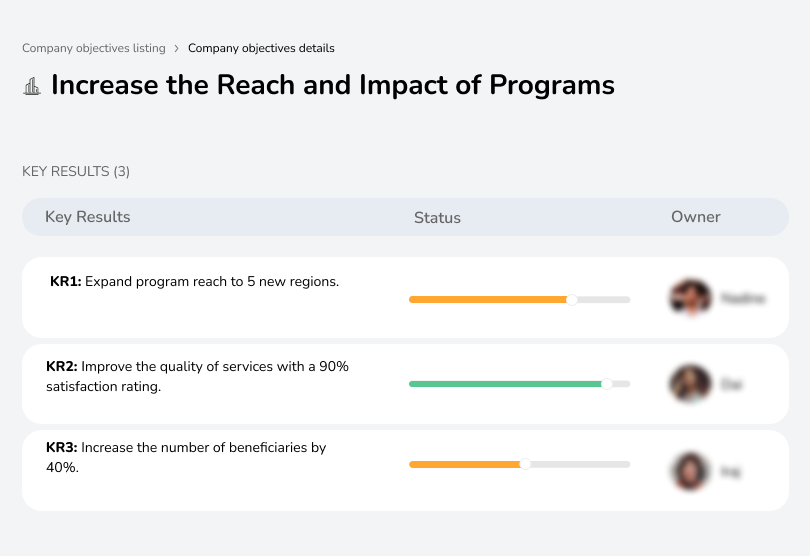

10. Challenge: Limited Beneficiary Impact

Objective: Increase the Reach and Impact of Programs

Owned by: Non-Profit Organization

Due date: 12 months

- KR1: Expand program reach to 5 new regions.

- KR2: Improve the quality of services with a 90% satisfaction rating.

- KR3: Increase the number of beneficiaries by 40%.

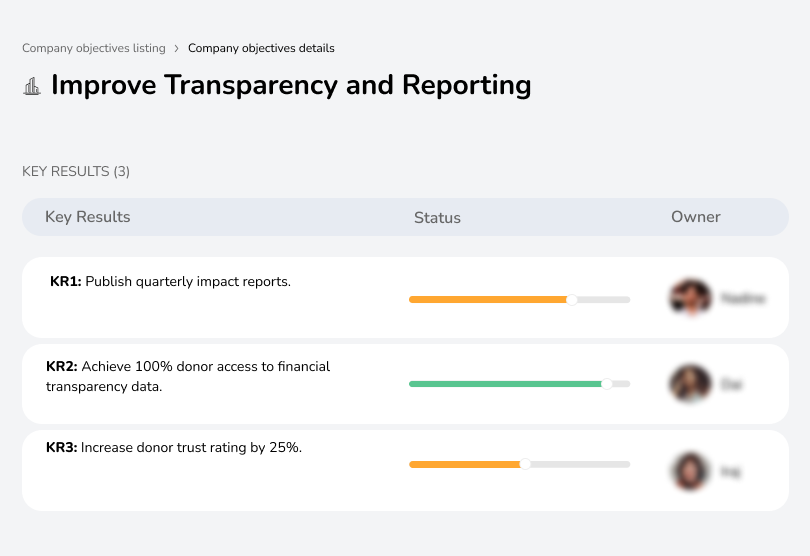

11. Challenge: Lack of Donor Transparency

Objective: Improve Transparency and Reporting

Owned by: Non-Profit Organization

Due date: 12 months

- KR1: Publish quarterly impact reports.

- KR2: Achieve 100% donor access to financial transparency data.

- KR3: Increase donor trust rating by 25%.

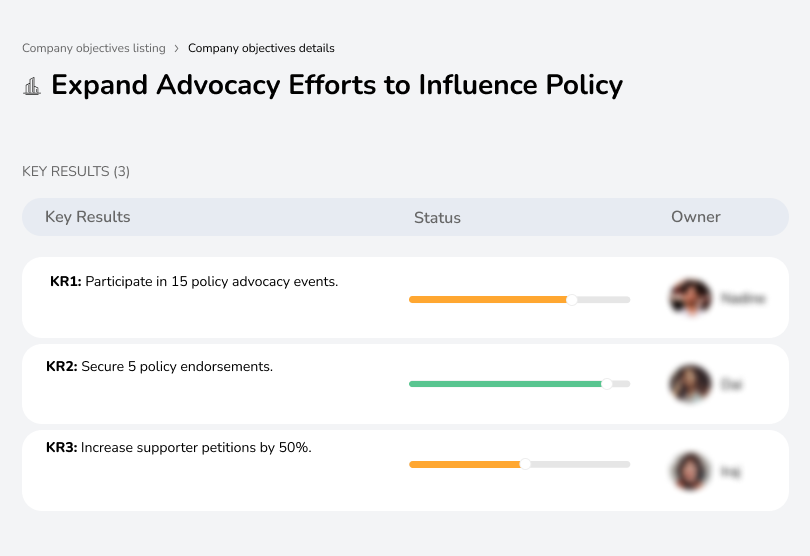

12. Challenge: Limited Advocacy and Policy Influence

Objective: Expand Advocacy Efforts to Influence Policy

Owned by: Non-Profit Organization

Due date: 12 months

- KR1: Participate in 15 policy advocacy events.

- KR2: Secure 5 policy endorsements.

- KR3: Increase supporter petitions by 50%.